|

|||||||

Innovating Shoe Manufacturing using Advanced Simulation Techniquesby Emanuele Carpanzano and Andrea Cataldo In order to handle the increasing complexity of distributed industrial manufacturing systems, there is a strong demand for methods and tools that support the designer in the analysis and optimisation of flexible infrastructures for the automation of production processes. We are currently investigating how emerging standards and advanced simulation techniques can be exploited successfully in the production of custom made shoes. Nowadays, many different approaches, methodologies and computer aided design tools can be employed in the analysis and optimization of complex industrial systems. As a consequence, the selection of the most appropriate techniques and tools for a particular system is critical. Before making any final decision, it is necessary to investigate the functionalities offered, compliancy with existing standards, and capacity for interoperability with non-proprietary instruments. We are currently working on a methodological approach to the structured design and simulation-based analysis and optimisation of manufacturing plants. The methods and tools used during the different phases of the design are illustrated with reference to an application in the shoe manufacturing sector. In particular, we describe an innovative plant for the production of customized shoes. This plant is located at the ITIA-CNR laboratory in Vigevano (Italy) and constitutes the pilot plant of a large European research project called EUROShoe, which began in March 2001 and is scheduled to finish in June 2004.

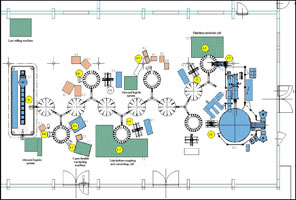

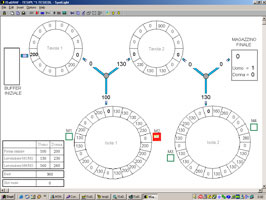

EUROShoe is a complex and ambitious project with thirty-five academic and industrial partners from ten different European countries. It aims at a dramatic renovation of the concept of shoes as products and of their production, based on a transformation from mass-produced to mass-customised goods. This product evolution goes in parallel with a transformation of footwear companies into distributed and flexible enterprises capable of handling the complexity that such a radical change in the nature of the product implies and of mastering the associated new technological challenges. This implies a complete revision not only of the entire manufacturing process but also of the tools used to analyse and optimize the resulting innovative industrial system. For the sake of brevity, the methods and tools used for the design, analysis and optimization of the plant automation system are outlined with reference to the control and supervision of the transport line. In the shoe manufacturing plant that we consider (Figure 1), an innovative transport line is used to move the semi-finished shoes from one machining station to another according to a predefined operating schedule. In particular, the innovative molecular structure of the transport line (Figure 2) strongly enhances the modularity, scalability, integrability and reconfigurability of the production system, thus increasing the overall flexibility of the plant.

At the beginning of the design life cycle, the control and supervision system of the transport line was specified by means of UML (Unified Modelling Language) diagrams; in particular use-case, class, sequence and state diagrams were used to specify the systems modules, their relationships and their dynamic behaviour. The system architecture and functions were designed using the Function Block formalism defined by the IEC 61499 standard, which integrates object-oriented concepts and discrete event models to suitably support control software design. The functional model obtained was analysed and optimized by means of closed-loop discrete event simulations performed in the Simulink/Stateflow environment, where both the controller and the controlled process were modeled and simulated through state charts, as was the behaviour of the overall system. In this way, the correctness and performance of the solution proposed could be evaluated. In particular, a bottom up methodology was defined and exploited to study the system according to a modular approach. This enabled us to simplify the overall analysis process, to verify the correctness of the automation functionalities easily and to optimize the system performance from the very first phases of the design life cycle. Once the functional modules had been verified, the control and supervision algorithms were developed using the SFC (Sequential Functional Chart) formalism, which is an advanced discrete event modelling graphical language, directly derived from Petri nets, and included in the IEC 61131 part 3 standard, which defines programming languages for industrial PLCs (Programmable Logic Controllers). The SFC algorithms were analysed through closed loop discrete simulations in the ISaGRAF environment in order to verify their correctness and to optimize their performance. ISaGRAF is a CACSD (Computer Aided Control System Design) tool that allows the automation software to be structured using all five IEC 61131 languages and supports simulation functionalities for testing purposes, as well as automatic code generation facilities for different industrial systems. In order to perform the closed loop simulations, simplified models of the plant devices have been represented in ISaGRAF by means of suitable SFC modules and data structures. Moreover, to simplify the analysis of the simulation results, a simple 2D graphic animation was realized in ISaGRAF (Figure 2). Simulations have been performed by considering typical operating conditions, ie, typical production orders, and the results obtained show that the system is deadlock free and that the plant is well balanced, ie its resources are all used effectively. After verification and optimization of the automation functions and algorithms, the corresponding code was generated and implemented on the target industrial devices. We found that the simulation-based analysis techniques reduced the plant rump-up times and costs and improved overall system performance. Future work will concern the exploitation of the standards, methods and tools proposed for other industrial plants and their integration within an advanced CACSD tool for manufacturing systems. Links: Please contact: |

|||||||